News Center

Contact Information

Shenyang Youqi Science and Technology Co., Ltd.

Address: Fahaniu Town, Xinmin City, Liaoning Province

Email: xmdxxq21@126.com

Technical Department:

General Manager Xue +86-18640518184

Domestic Sales Department:

Manager Yang +86-15998838531

International Sales Department:

Manager Park +86-18602488252

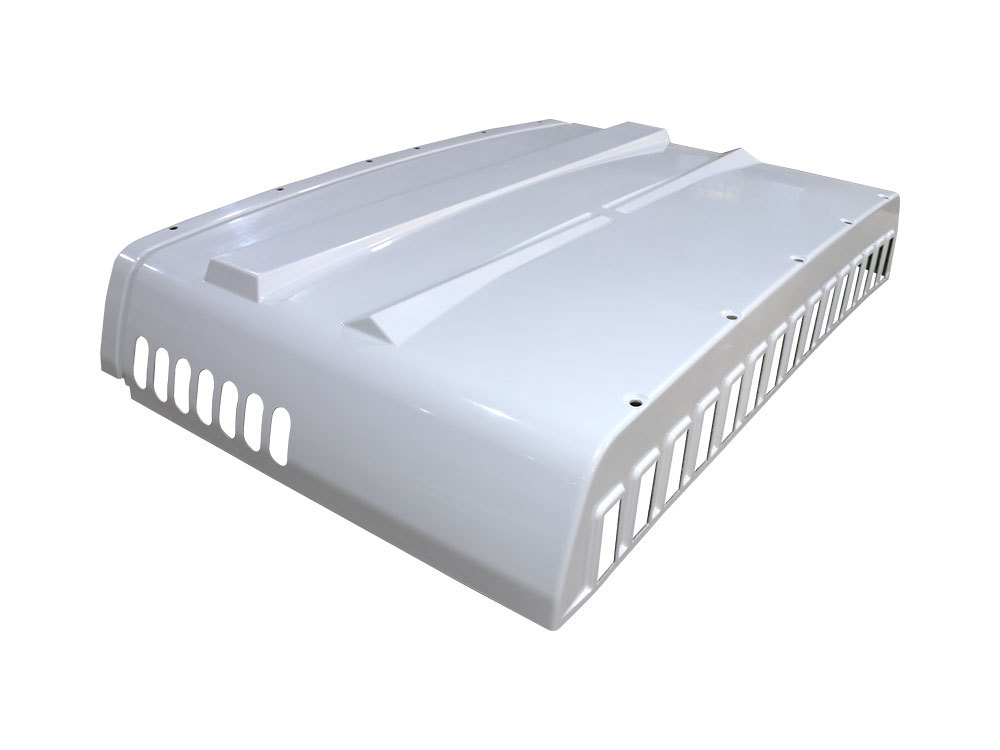

Why are many outer casing materials now choosing fiberglass reinforced plastic?

Published time:

2025-04-01

1. Lightweight and high strength Its relative density is between 1.5 and 2.0, only 1/4 to 1/5 that of carbon steel, but its tensile strength is close to, or even exceeds that of carbon steel, while its specific strength is comparable to that of high-grade alloy steel.

1. Lightweight and High Strength

With a relative density between 1.5 and 2.0, only 1/4 to 1/5 that of carbon steel, its tensile strength is close to, or even exceeds that of carbon steel, while its specific strength is comparable to that of high-grade alloy steel.

2. Corrosion Resistance

FRP is an excellent corrosion-resistant material, exhibiting good resistance to atmospheric conditions, water, and common concentrations of acids, alkalis, salts, various oils, and solvents. It has been applied in various aspects of chemical corrosion prevention and is gradually replacing carbon steel, stainless steel, wood, and non-ferrous metals.

3. Good Electrical Properties

It is an excellent insulating material used in the manufacturing of insulators. It maintains good dielectric properties even at high frequencies. Its good microwave permeability has led to widespread use in radar antenna radomes.

4. Good Design Flexibility

(1) Various structural products can be flexibly designed to meet usage requirements, ensuring good product integrity.

(2) Materials can be fully selected to meet product performance needs, such as designing products with corrosion resistance, resistance to instantaneous high temperatures, exceptionally high strength in a specific direction, or good dielectric properties, etc.

5. Excellent Processability

(1) Forming processes can be flexibly selected based on product shape, technical requirements, application, and quantity.

(2) The process is simple, allowing for one-time molding, resulting in outstanding economic efficiency. This is particularly advantageous for products with complex shapes, difficult molding, and small quantities.

Keywords:

Related news

Fiberglass, a name that sounds both modern and technologically advanced, is actually a new type of composite material made from resin and glass fiber through a composite process.

2025-05-14

The development prospects of fiberglass robots

Fiberglass robots are actually quite common now. Have you ever seen the intelligent service robots in hospitals? Their outer casings are made of fiberglass. This is because fiberglass offers high strength, light weight, excellent corrosion resistance, impact resistance, and a long service life, making it more durable than traditional materials. Of course, CT machine casings in hospitals, wastewater treatment tanks, large architectural art pieces, etc., can all be made of fiberglass. Its applications are quite extensive.

2025-04-01