News Center

Contact Information

Shenyang Youqi Science and Technology Co., Ltd.

Address: Fahaniu Town, Xinmin City, Liaoning Province

Email: xmdxxq21@126.com

Technical Department:

General Manager Xue +86-18640518184

Domestic Sales Department:

Manager Yang +86-15998838531

International Sales Department:

Manager Park +86-18602488252

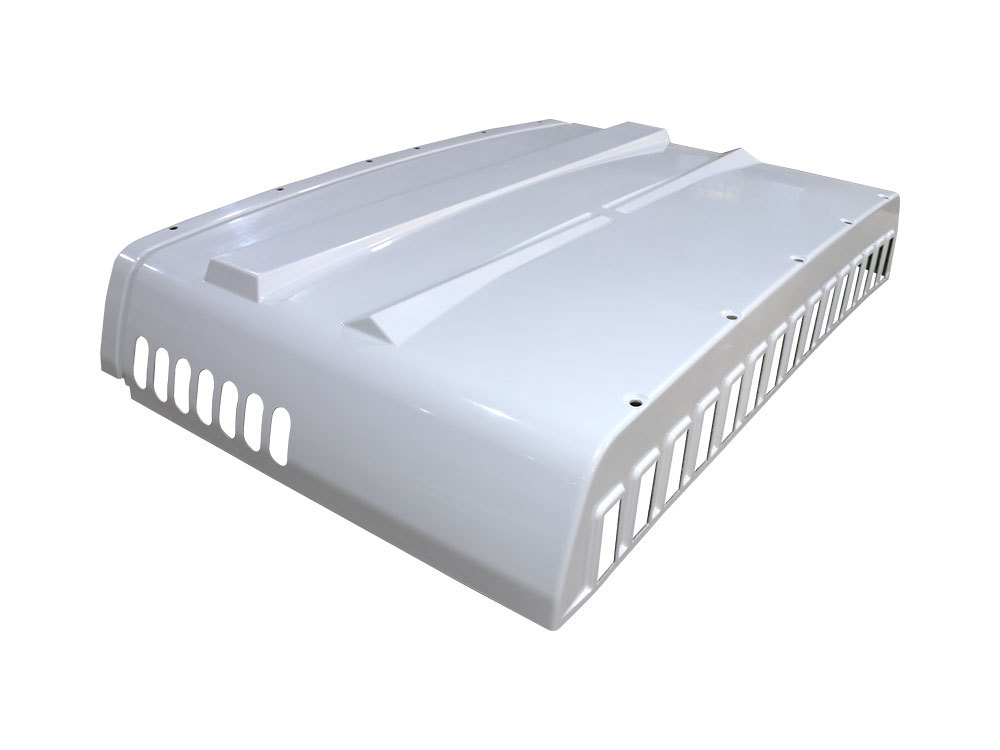

Fiberglass products

Published time:

2025-05-14

Fiberglass, a name that sounds both modern and technologically advanced, is actually a new type of composite material made from resin and glass fiber through a composite process.

Fiberglass Products

Fiberglass, a name that sounds both modern and technologically advanced, is actually a new type of composite material made from resin and glass fiber through a composite process. Due to its many advantages, such as light weight, high strength, corrosion resistance, and good insulation, fiberglass products have been widely used in many fields. This article will delve into the characteristics, manufacturing process, application fields, and future development trends of fiberglass products.

I. Characteristics of Fiberglass Products

The reason why fiberglass products can stand out among many materials is mainly due to their unique properties. First, fiberglass has an extremely high strength-to-weight ratio, which means that under the same weight, its strength is far higher than that of traditional metal materials, making it very suitable for occasions where large loads need to be supported but weight reduction is desired. Second, fiberglass has excellent corrosion resistance and can remain stable for a long time in various corrosive environments such as acids, alkalis, and salts, which makes it very popular in the chemical and environmental protection industries. In addition, fiberglass also has good insulation performance and thermal stability, and can maintain its performance unchanged in high or low temperature environments, further expanding its application range.

II. Manufacturing Process of Fiberglass Products

The manufacturing process of fiberglass products mainly includes raw material preparation, mold making, hand lay-up molding, curing, demolding, and post-processing steps. In the raw material preparation stage, resin and glass fiber are mixed in a certain proportion to ensure that the material properties meet the design requirements. Mold making is customized according to the shape and size of the product, and the accuracy of the mold directly affects the appearance and quality of the product. Hand lay-up molding is to lay the mixed resin and glass fiber in the mold layer by layer, and manually operate them to make them closely combined. In the curing stage, the resin is cured by heating or natural placement to form a stable product structure. After demolding, post-processing work such as grinding and trimming is also required to improve the appearance and performance of the product.

III. Application Fields of Fiberglass Products

The application fields of fiberglass products are extremely wide, covering almost all aspects of the national economy. In the construction industry, fiberglass is used to make roof, wall, and door and window components, which not only reduces the weight of buildings but also improves thermal insulation performance. In the transportation industry, fiberglass products such as car bodies, hulls, and aircraft components effectively reduce energy consumption and improve operating efficiency. In the environmental protection field, due to its corrosion resistance, fiberglass is widely used in wastewater treatment equipment, exhaust gas treatment towers, and other environmental protection facilities. In addition, fiberglass also plays an important role in amusement facilities, sports equipment, and agricultural irrigation equipment, demonstrating its strong application potential.

IV. Future Development Trends of Fiberglass Products

With the advancement of technology and the strengthening of environmental awareness, the future development trends of fiberglass products show the following characteristics: First, high performance, improving the strength and toughness of fiberglass products by improving formulas and processes to meet higher-end application needs; second, green, using environmentally friendly resins and recycled glass fibers to reduce environmental pollution during production; third, intelligence, combining technologies such as the Internet of Things and big data to develop fiberglass products with intelligent monitoring and remote control functions to improve product added value; fourth, customization, using advanced technologies such as 3D printing to achieve personalized customization to meet the special needs of different customers.

In short, fiberglass products, with their unique properties and wide range of applications, are playing an increasingly important role in modern society. With continuous technological advancements and market expansion, the future development prospects of fiberglass products will be even broader, contributing more to the sustainable development of human society.

Keywords:

Related news

Fiberglass, a name that sounds both modern and technologically advanced, is actually a new type of composite material made from resin and glass fiber through a composite process.

2025-05-14

The development prospects of fiberglass robots

Fiberglass robots are actually quite common now. Have you ever seen the intelligent service robots in hospitals? Their outer casings are made of fiberglass. This is because fiberglass offers high strength, light weight, excellent corrosion resistance, impact resistance, and a long service life, making it more durable than traditional materials. Of course, CT machine casings in hospitals, wastewater treatment tanks, large architectural art pieces, etc., can all be made of fiberglass. Its applications are quite extensive.

2025-04-01